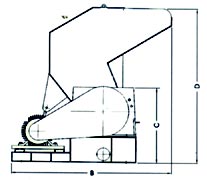

The dimensions of the feed hoppers allow the milling of any defective part, without the need of a previous cut. In these equipments can be introduced directly: refrigerator doors, large diameter tubes, boxes, thermoforming bottles, etc. Constructed entirely of steel, they are widely dimensioned, offering great resistance.